end wall flashing detail

Beyond end of lintel cavity insulation not shown for clarity of detail sealant note. It protects specific areas within exterior wall assemblies and creates an impervious barrier for water to follow to the face of the exterior finish.

Place silicone sealant at all overlaps.

. For chimneys specifically base flashing is the first of two types of flashing applied and sits below the second type of flashing counter flashing. Prior to the installation of the parapet coping a metal flashing material shall be adhered to the structural wall. This color matched flashing also provides a professional finishing touch to your roof.

Joints are soldered or sealed see Figure 2. Additional information for flashing single-wythe walls particularly architectural concrete masonry walls and means for providing a higher level of structural continuity at flashings is contained in TEK 19-2A ref. 54 Exterior Continuous Insulation CI at Walls.

The maximum parapet wall height is not to exceed the width of a 10-ft. The Type Of Screw Depends On The Material Of The Wall. A sidewall is a junction between a wall and a sloped portion of a roof.

10 Lap Screws Metal to Metal With Sealant Washer. Mark your trim on the hem side 6 from the end and ⅛ up from the hem. Except where walls are brick the vertical part of the sidewall flashing should extend up behind the exterior wall covering just like with headwalls.

End dams are constructed by cutting and folding the flashing material. Deck joist Ledger Spacer behind ledger Housewrap or building paper Housewrap or building paper Exterior sheathing Flashing drip-edge Z-flashing 2 Z-flashing 1 Deck board Siding Gap. The metal flashing shall lap the parapet wall.

Fasteners close to folded edges generally cause the least distortion. A reglet trim may also be required. Apply siding over the rigid foam insulation.

Using a pencil or a sharpie mark where the flashing and gable meet. How To Install Foam Closures For Endwall Flashing 1. Through wall flashing is above grade waterproofing.

Install your underlayment completely and your shingles up to where the wall begins so that the first piece of flashing or the corner flashing will rest on a shingle. The installation of the coping-to-wall termination provides waterproofing protection and allows for differential movement between the two construction components. This collection of 18 articles animations and videos identifies the critical roof flashing areas illustrates durable roof flashing details and shows how to flash roofs.

The advice given in this manual is consistent with the requirements of the Building Code of Australia and is aimed at ensuring. Drip edge metal valley flashing dormer chimney and kick-out flashing shed water away from the connections between roofs walls chimneys and other building assemblies. It protects areas within the exterior wall assembly starting from.

For front end-walls where roofing shingles meet siding the metal flashing strip should be bent using a metal brake to extend at least 2 inches up the vertical wall and at least 3 inches onto the last shingle course. Apply roof underlayment over roof deck and up sidewall over the rigid foam insulation. On the adjacent piece pry open the hem of the endwall by 6 to allow it to slide into the notched piece.

To make corner flashing take your tin snips and cut a 45-degree line. The cap flashing is then locked over the edge strips. 46 Horizontal Rain Screen Furring for Vertical Siding.

62 Vented and Unvented Roof Assemblies. On center and a minimum of 10 ft. 330 769-3546 Toll Free.

Leave approximately one inch past the edge of the gable trim on both ends of the flashing. Ad Shop Roofing Materials for Less. The detail illustrates a copper cap flashing installed over a masonry wall.

Used in conjunction with closure strips or butyl tape it reliably protects against water infiltration. Continuous wood blocking is first securely anchored to the top of the masonry and covered by a layer of building paper. The down direction harnesses the force of gravity and the out direction gets the water away from the building enclosure assemblies openings components and materials.

How Doers Get More Done. Typical Flashing Joint and End Dam. Apply self-adhesive flashing over the top edge of the wall flashing diverter and rigid foam insulation Figure 6.

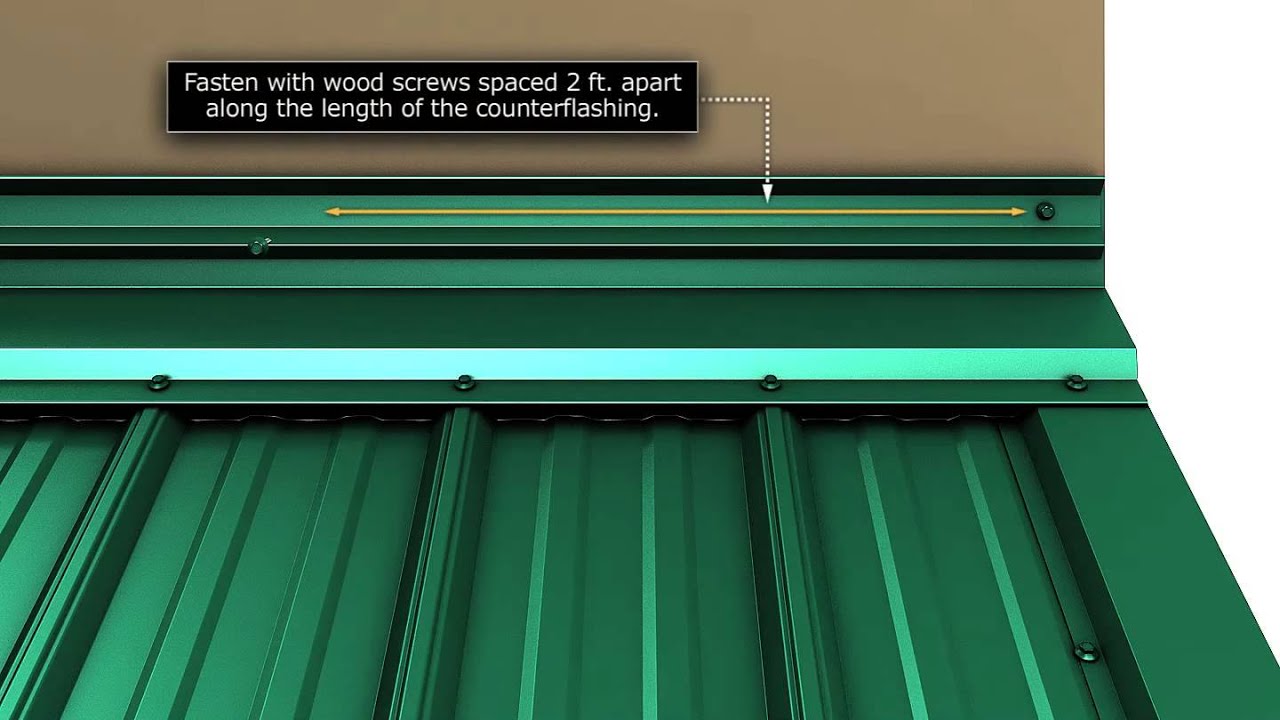

Prior to fastening your endwall double sided butyl tape should be placed 1 from the edge of the endwall. Then take the flashing off and fold it down where you marked it. Correct detailing of LYSAGHTroof and wall flashing has more than cosmetic importance - it is essential in ensuring the wet weather performance of the cladding.

At the ends the flashing is detailed as shown to provide an effective dam preventing moisture from draining back into the. End dams should be constructed wherever flashings terminate within a wall to prevent water from simply flowing off the side of the flashing within the masonry wall rather than being directed to weeps where it can flow out of the wall. Prefabricated flashing end dam carry flashing ½ min.

Apply construction tape over the self-adhered flashing Figure 7. Hyload Headquarters 5020 Enterprise Parkway Seville Ohio 44273 Email. Correct flashing and detailing will improve the overall appearance of the finished job.

Gravity is the driving force behind drainage. Additional fixing may need to be considered in wind-exposed locations eg. Flashing edges beneath cladding normally only require nominal attachment to battens.

From any corner or end of wall. 10 Screws With Sealant Washer To Fasten Into The Wall. Otherwise dripping water will leave its mark along the siding.

10 Linear Feet Of Double Sided Butyl Tape. With metal cutting snips notch out the hem of the endwall by cutting along the traced line. Flashing is generally fixed to cladding or other flashing sections using rivets or self-drilling screws.

23 Roof-to-Wall and Deck-to-Wall Flashing Home Builders Guide to Coastal Construction Page 3 of 3 Figure 3 Deck ledger flashing. In general the sooner water is directed out the better. Structural elements may vary and are shown for illustration only.

Plates and fasteners get installed at the seamvertically up the wall at 12 in. 12 Tube Silicone Sealant. Technical Fact Sheet No.

Gibraltar End Wall Flashing is made from painted 29 gauge galvanized steel. The End Wall Flashing provides protection where a roof intersects with a vertical wall. End dam placed prior to through-wall flashing 2 recommended.

Where the step flashing terminates along a sidewall is a common trouble spot for moisture problems. 55 Wall Assembly Example. Continuous copper edge strips are then fastened to the wood blocking.

Laps are heat-welded and the process continues until the wall flashing is complete. 1 Piece Endwall Flashing - WS-28 Roof Pitch Required. The horizontal part of the flashing will vary depending on the type of roof-covering material.

International masonry institute team masonry detailing. Adjacent pieces are lapped at least 6 and sealed see Solder and Sealants section for sealant recommendations. By folding down the flashing you keep water from rolling between the top of the gable trim and the end wall flashing.

10 Linear Feet Of Outside Foam Closures. The face of the backing wall to the face of the exterior finish Fig. Wherever long runs of copper flashing are required multiple sheets of copper flashing are used.

Flashing single wythe walls at the ends of bar joists which utilize wall pockets for bearing is shown in Figures 8 and 8a. The best solution is a preformed or custom-bent kick-out flashing to divert the water away from the siding.

Outlookers Framing Google Search Roof Construction Roof Detail Exterior House Remodel

Architectural Details Roofing Systems Standing Seam Roofing Standing Seam Standing Seam Roof Roofing

Pin By Silin He On Detail Expansion Joint Masonry The Expanse

Typ Window Head Cavity Wall Brick Veneer Cavity Wall Brick

How To Install Endwall Trim For Union S Masterrib Panel Metal Roof Installation Roof Installation Roof Truss Design

Parapet Wall To Curtain Wall End Parapet Curtain Wall Membrane Roof

Pin By End Studio On Porch Ideas Shingling Masonry Wall Roof Maintenance